I blew my budget on it but it got me interested in metal machining and mechanical engineering.

PARALAX GROWBOT FULL

Unfortunately it wasn't a complete success (it ran but only under full human control, the controllers I built and the available software wasn't up to the task -also all my money was going into this one project for several years!) due to a number of issues both mechanical and electronic. The learning curve was steep and the price even steeper, but I finished a basic version back in the early 90's. It was far and away more complex than anything I had attempted up to that point but I knew I had to try. I was inspired several years ago when I subscribed to Robotics Age magazine when a 1984 edition featured the Odex I. I'm also investigating aluminum anodizing, that would give the whole project a very nice look!

I am taking vacation all next week so I should be able to get a lot done. Most of the hardware will be custom built for this project.

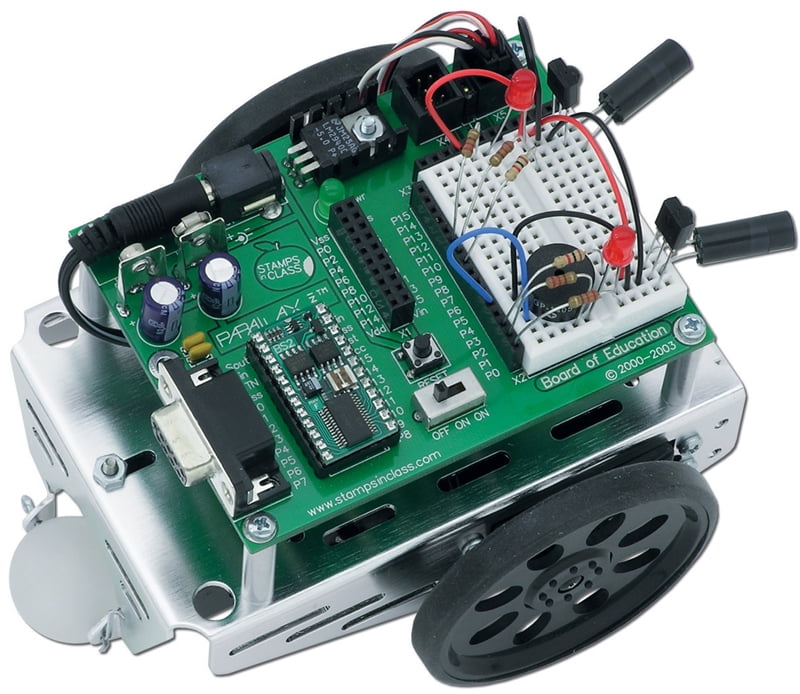

PARALAX GROWBOT CODE

I'll add photos as I go along if anyone is interested.Īlmost done with the CAD drawings, will convert them to G code for the CNC mill (I have a Tormach 770 for those that are interested). This is actually my second Hexapod using this basic design but with access to better machining (CNC) capabilities and more modern electronics I expect to have more success this time around (the original was built in the 80's and had very limited capabilities) If I can do that, then it will be a success for me! My big goal is for it to be able to climb stairs with a minimum of input from myself. I plan on using Rodney Brooks's behavioral programming ideas for this robot. The rest of the legs will follow shortly after that (nice thing about a CNC is that design changes are easy to incorporate and reproduce!). I expect the final weight of the robot to be around 125 pounds and it will stand up to a maximum of around 4.5 ft. The goal is to get the mechanical parts for a single leg together before the end of the year and have the basic individual leg programming completed before spring. These controllers will be networked together with a master prop board running the show. The HB-25 motor controllersl are used to drive the 12 volt motors and 6 custom propellor boards will be used to control the legs. I'm using Parallax parts as much as possible but some things like the linear actuators were ordered elsewhere. Then it all goes into a CNC mill to make the parts! The CAD drawings were finished last night so the next step is cutting out the aluminum stock. I built a wooden version of one leg to validate the design,clearances and interferences.

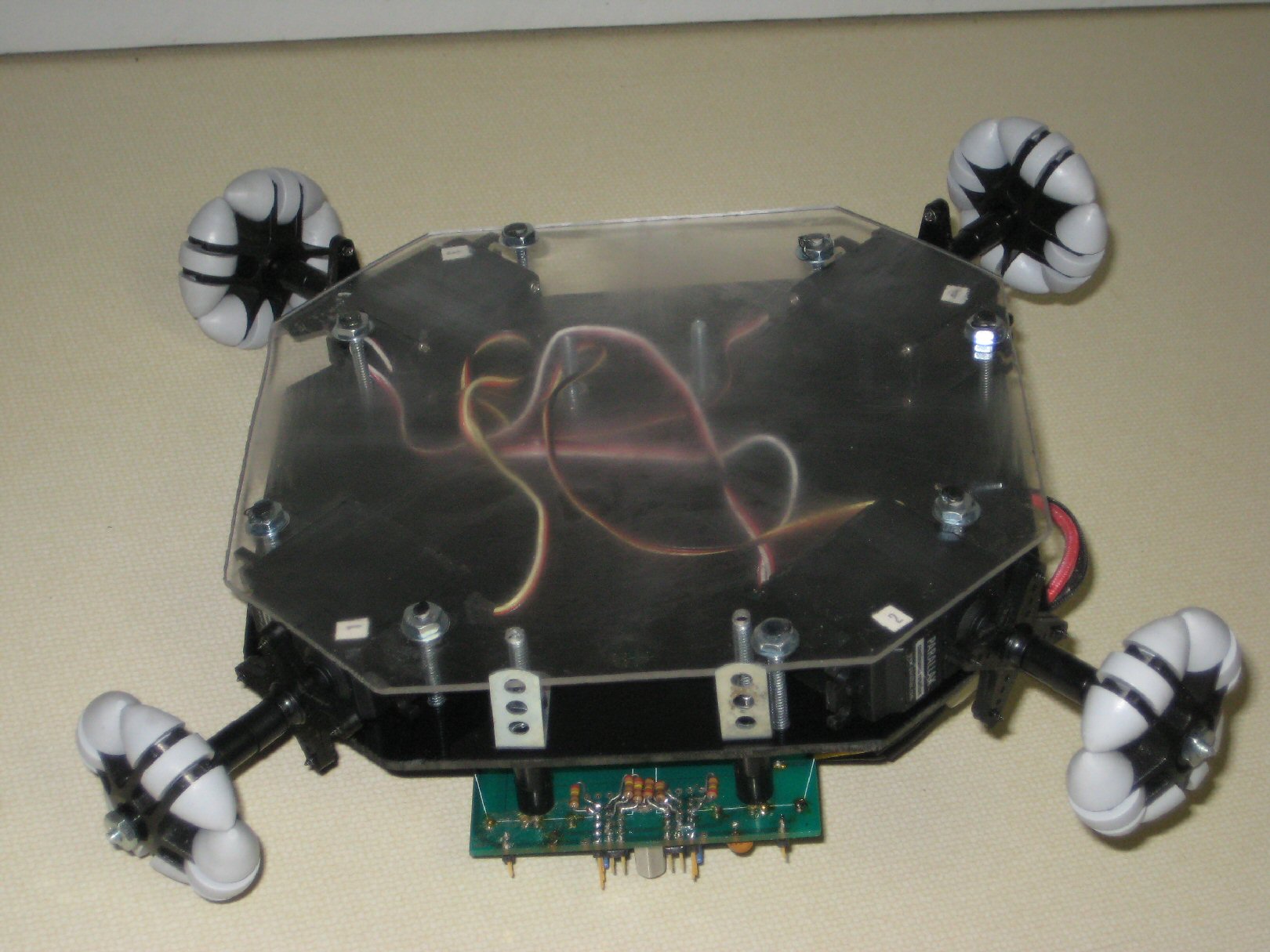

Linear actuators drive two axis and the third uses a large gear motor. All moving parts will be on bearings or bushings, there will be 24 per leg. Each leg will have 3 drive motors and will use a design similar to the old Odex I (look it up if the name isn't familiar!). This robot will be a Hexapod based on a circular body. It now runs on a 10 direction subroutine.I've started the design work on my next creation which will be a bit different than the last few I've built. Waiting of a stable robot before I start the programming. It has been a learning experience for sure. A picture speaks 1,000 words and you will soon see what I mean. lol Included are some pics and waiting for the videos to be approved. The body is very easy to add or subtract and position servo motors as desired. I plan on trying the 3 wheel setup as a last atempt. Silicone coated or rubber seem to be the only way to go. I suggest anyone thinking about omniwheels, should forget about hard plastic wheels. They have no traction at all even in smooth surfaces. I think I am as far as i can go with hard plastic wheels. I also changed the wheels to single wheels instead of double wheels. It worked a little better then the circuit board prototype but still far from perfect. It is easy to change angles and motor placements. I used a peice of weather stripping on the top of the servo to resctict movement. I constructed a body using 2 peices of plexaglass and sandwitched the servos inside. Here is the new addition to my Omniwheel Growbot.

0 kommentar(er)

0 kommentar(er)